More than 200 years ago at the outset of the Industrial Revolution, humankind began to use machines to mass-produce products. This machinery was designed to perform certain steps in the manufacturing process and to replace human laborers in particular jobs. Now, following assembly line work and computerization, industry has now arrived at Version 4.0 and begun to interconnect machines in networks. But deep inside these manmade tools, there’s a fair amount of artistic potential, and this is amply illustrated by the new “Creative Robotics“ exhibition at the Ars Electronica Center. We recently sat down with Johannes Braumann, director of Linz Art University’s Robot Lab, applications engineer at Linz-based KUKA Roboter CEE GmbH, to find out more about some of the creative capabilities of these programmable devices and versatile robotic arms.

Two of KUKA’s industrial robots are featured in the Ars Electronica Center’s “Creative Robotics” exhibition. One is the KUKA LBR iiwa. What are the special characteristics of this model?

Wolfgang Schinnerl: The name of KUKA’s innovative LBR iiwa robots give an indication of what this is all about. LBR stands for lightweight robot, and iiwa for intelligent industrial work assistant. The built-in sensors endow the iiwa with a “sense of touch,” which means that it recognizes obstacles, reacts to them, and thus can work together directly with human beings. One really cool feature is the robot’s capability of learning routines that a human shows it how to do.

Wolfgang Schinnerl and Johannes Braumann during calibration works. Credit: Martin Hieslmair

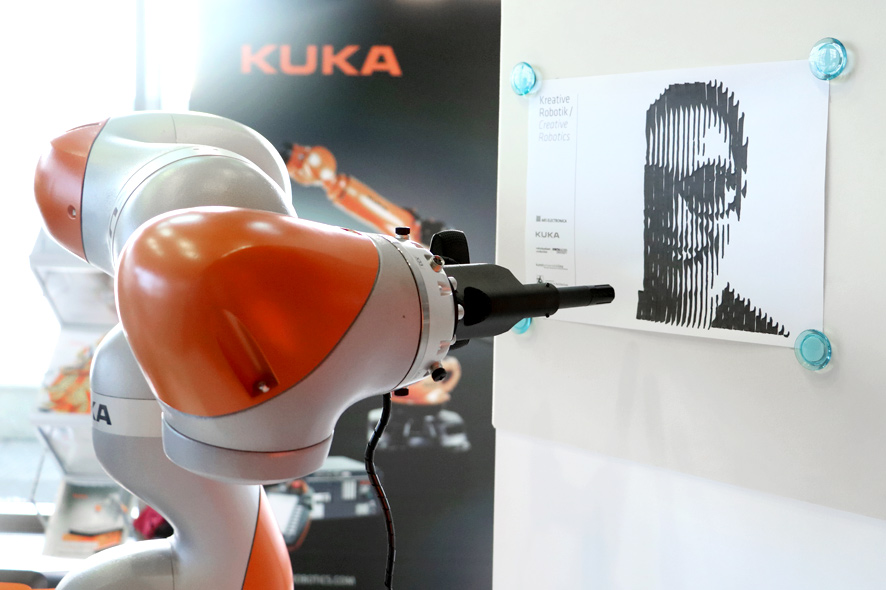

One of your positions is director of Linz Art University’s Robot Lab. And one of the Lab’s projects is “Robotic Calligraphy” in which a KUKA LBR iiwa takes a pen and, in its own inimitable way, draws a person’s portrait. Tell us more about this.

Johannes Braumann: At Linz Art University’s Robot Lab, we develop creative new robot applications, but the point of this isn’t to replicate industrial processes or shave fractions of a second off manufacturing sequences. Instead, we work in a very open way with students in all the college’s programs—industrial design, architecture, fashion & technology, interface cultures, etc.—and we develop new approaches to utilizing robots in ways that go beyond industrial mass production. These range from individually customized products to cinematic robotics installations. “Robotic Calligraphy” follows suit, in that we developed a rendering strategy that’s feasible in this form only with the precision of a machine. So, this isn’t a matter of a machine competing with a human artist; rather, this gives rise to interesting new strategies.

KUKA robots were also shown at the Ars Electronica Festival 2015. Credit: Florian Voggeneder

Artist Chris Noelle uses a KUKA KR16 industrial robot to do works of light painting. How is this robot normally deployed and how is it controlled in this application?

Wolfgang Schinnerl: The KUKA KR16 robot has a 16 kilogram weight capacity. It’s a very flexible product for low-load tasks, so it can be put to use performing a wide variety of jobs. Handling assignments such as transporting components, as well as welding, casting, milling, measuring, testing, packaging and palettizing are just a few of many areas of application. In most instances, a superordinate control system determines which individual tasks are assigned to which particular robots. The latest approaches make it possible to program the robot directly into the superordinate control system and thus maintain the centralization of the program logic.

The KUKA KR16 industrial robot also had a starring role in the „Incremental Forming“ project that was presented at the Ars Electronica Festival in September 2015. And that brings us to so-called mass customization—will this type of robot now make it possible for mass production to be more individual?

Johannes Braumann: The exciting thing about machines is that it actually doesn’t make a difference if a machine executes the same motion a thousand times or if it carries out a thousand different motions. The challenge is to quickly and efficiently instruct the robot how to perform these thousand different operations. However, purely technical issues aren’t the only considerations here. For instance, how does a designer configure a product that can then be modified by the customer? What liberties are to be offered to users without overly restricting them thereby? So, as you can see, mass customization is a highly complex, multifaceted topic, but this is precisely why significant progress in this area won’t necessarily emerge in the mass manufacturing sector but rather in artistic-technical fields like architecture and design.

In 2010, you and Sigrid Brell-Cokcan established Association for Robots in Architecture, an association to support research in applied creative robotics. To what extent will robots revolutionize architecture?

Johannes Braumann: I believe that, at this point, few people doubt that machines will be building complete houses someday. After all, the demographic shift alone leaves few other possibilities open. The big question, however, is how these processes will function in detail. I don’t think that it’s necessarily expedient over the long term to simply automate existing manual construction procedures and, for instance, invent robots that can lay bricks. By the same token, we have to ask whether it makes sense to take small-scale 3-D printer processes and supersize them to an architectural scale. I think that, instead, we’ll have to come up with new manufacturing processes that are precisely adapted to the strengths and weaknesses of machines. In this context, wood construction methods are especially interesting since there’s a lot of high-tech and automation already in use in this field.

Tip: Have your own portrait painted by an industrial robot! In February 2016 there is an opportunity at the Ars Electronica Center Linz – from Tuesday to Friday 11 AM-11:30 AM and 3 PM-3:30 PM and on weekends 10 AM-12 AM and 1 PM-5 PM. The two KUKA robots will be part of the temporary exhibition “Creative Robotics” at the Ars Electronica Center until the end of February 2016.

Johannes Braumann is a guest professor at Linz Art University, and heads the school’s Robot Lab set up by KUKA CEE. In 2010, he and Sigrid Brell-Cokcan founded the Association for Robots in Architecture; the organization’s aim is to foster the use of robots in creative industries. He’s the chief developer of KUKA|prc (parametric robot control) software that provides a simple way to program parametric robotic processes, and that’s used by numerous universities and R&D labs as well as private-sector associates for research, teaching and production.

Wolfgang Schinnerl is an applications engineer at KUKA Roboter CEE GmbH in Linz and the company’s go-to guy for answers to technical questions about the LBR iiwa and human-robot collaboration. He supports clients and associates in conceptioneering, implementing and optimizing robot cells.