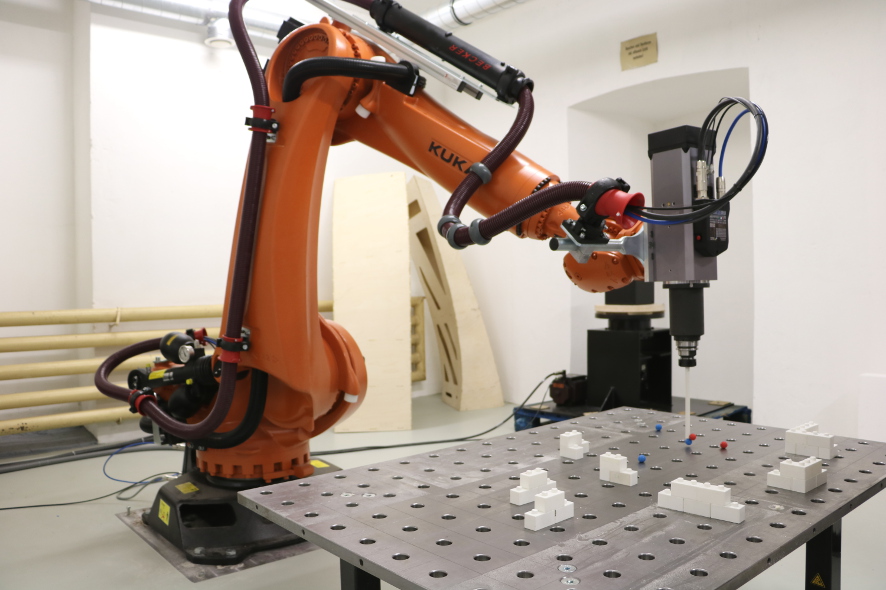

This takes place under the auspices of Linz Art University’s Robot Lab under the direction of Johannes Braumann. The facility’s efforts go far beyond the realm of conventional automation to come up with totally new applications for industrial robots. Creative industries no long employ robot arms strictly for assembly-line manufacturing; they’re now the key to innovative new processes that make it possible to turn out customized products.

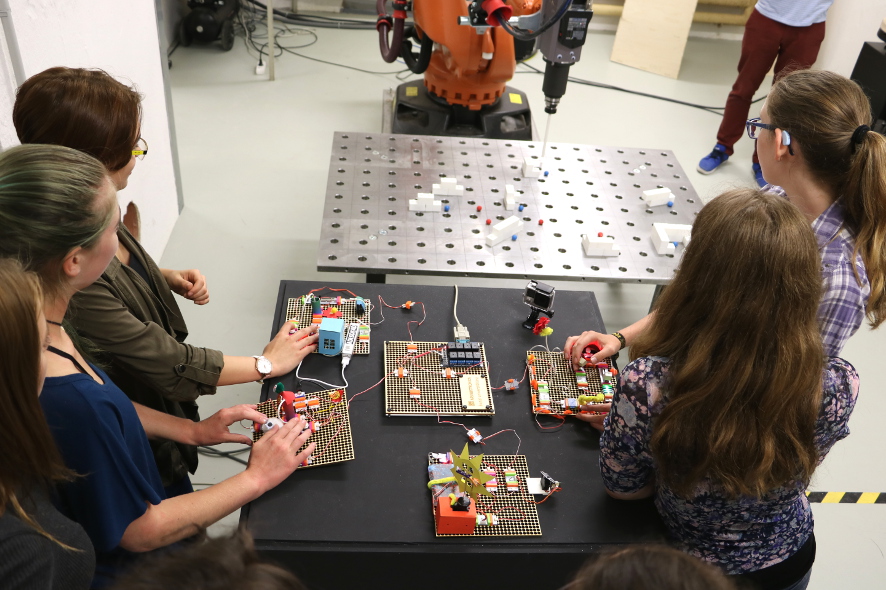

Beginning in the 2016-17 school year, “Hack the Robot” will be one of the highlights of the Ars Electronica Center’s educational program. The workshop was recently put through a pre-premiere test by a class at Bad Leonfelden High School and their teacher, AEC Ambassador Elke Hackl.

During that trial run, we had a chance to chat with Johannes Braumann about new deployment possibilities for industrial robots, Linz Art University’s Robot Lab, and the new robotics workshop for kids and young people.

KUKA is a pioneer in the field of robotics and automation technology, and one of the world’s leading manufacturers of industrial robots. In what areas are KUKA robots usually deployed?

Johannes Braumann: The beautiful thing about KUKA robots is that they can be used to do so many different things. Depending on what you install on the end of the robot arm, it can perform a wide range of tasks. The classic area in which KUKA robots are deployed is the auto industry, but now there are also a lot of very innovative ways in which robots are being used, and above all in creative industries—architecture, design and many artistic disciplines.

Linz Art University has a special Robot Lab. What goes on there?

Johannes Braumann: The unique and exciting thing about our Robot Lab is that it’s not a workshop but a laboratory to which the entire university and our partners and associates have access. So, it’s not a service provider that lets students upload a 3-D file and pick up their model the next day. Instead, we impart essential skills to students, and work with them to develop new and innovative processes. Due to Linz Art University’s broad academic spectrum, the diversity of the projects we carry out here is really great. We build models and mockups for industrial designers, produce conceptual art projects with students in media art, and work in the textile field with the new Fashion & Technology program. And we also deploy robots in research projects—for instance, in carbon technology and solar technology. This is really exciting for us because it lets us try things out in a creative context in a wide variety of fields. Optimizing existing processes down to the last millisecond isn’t what this lab is all about. We do R&D on innovative new robotic applications. And it’s always really exciting for us to see how such creative-experimental ideas can ultimately make their way into the private sector.

Credit: Benjamin Greimel

What has been Robot Lab’s most interesting project to date?

Johannes Braumann: One that I find particularly fascinating is Print a Drink by Benjamin Greimel, because it has succeeded in making the quantum leap from student project to start-up, and it’s now making a name for itself worldwide. This was a spinoff of Machinic Food Design, a course that I supervised together with Sigrid Brell-Cokcan and Elke Bachlmair as part of the Industrial Design program. The students were instructed to find new ways in which robots could be used for the purpose of food design. But the point wasn’t to employ robots to do jobs now done by hand only to do them faster and more precisely; instead, the assignment was to really develop new processes that are custom-tailored to robots’ capabilities. Benjamin had the idea to have the robots do 3-D printing with fluids in fluids. The whole thing began in very “analog” fashion with lots of material experiments and the development of a new tool, and the robot’s part in this was actually just a small but essential step at the end. Ultimately, Benjamin came up with a new application that’s now being displayed at trade fairs and exhibitions, and is really getting rave reviews from spectators.

What’s the thinking behind now using KUKA robots in workshops for kids and young people?

Johannes Braumann: Generally speaking, you can say that it’s just a lot of fun to work with robots because robotics is so multifaceted. When most people hear the word robot, the image that comes to mind is something totally different—maybe Star Wars, or lawnmower robots or aerial drones. But we work with very large robots, with industrial robots, and they’re a great way to get youngsters enthused about new technologies. We want to show that a tour of a BMW plant isn’t the only time you see these machines, and you don’t need to study mechanical engineering for five years to get your hands on one. These really are technologies open to all comers, and they enable kids and young people to experiment and implement their own projects.

Robotics is simply a very wide-ranging field. It’s not only mechanical engineering; it also entails informatics and electrical engineering, and it can also involve art, design and architecture. This is what we especially want to convey to members of the young generation.

Programming a robot sounds terribly complex and hard to learn. So, how does this play out in a workshop for kids and young people?

Johannes Braumann: Nowadays, programming doesn’t have to be complicated anymore. One of Robot Lab’s biggest fields of research involves designing interfaces to make these technologies accessible. In collaboration with KUKA|prc, we’ve developed software for simple, visual programming of robots, and this software is now in use worldwide.

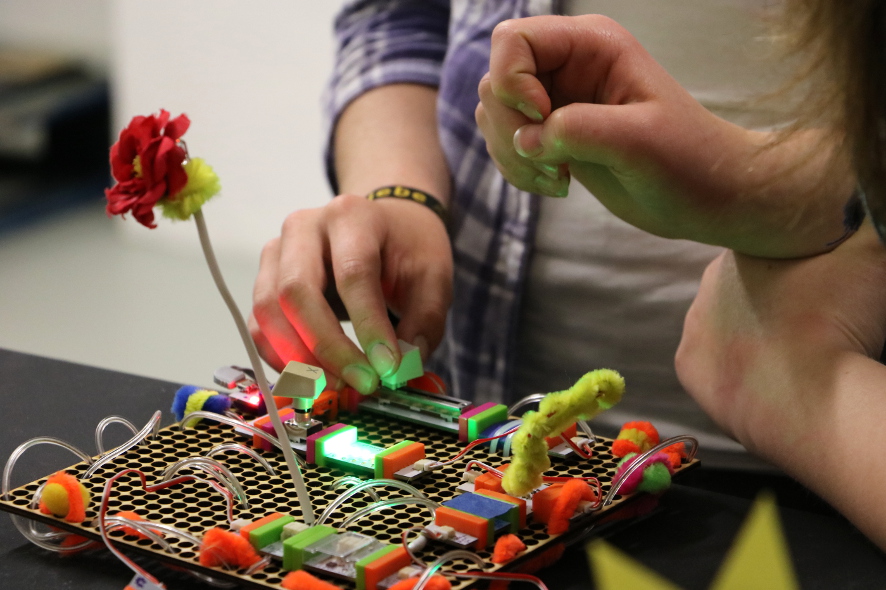

For kids and young people, we’re developing totally new interfaces that youngsters can learn completely intuitively and that lets them safely interact with robots. The same user-friendliness that enables youngsters to work successfully with the motors in an electrical erector set can also be built into a system for operating a large robot. Our aim isn’t to turn elementary school pupils—or even university students—into robotics engineers; it’s to help them overcome their fear of technology and to impart fundamental skills that put them in a position to creatively experiment in ways that are simple and safe.

And just how do you go about hacking a robot?

Johannes Braumann: OK, in the workshop we’re holding today, we’re using littleBits, which were developed by MIT, to create our own interface with which we can link up the littleBits to a complete robot arm in order to control it. Regular robot controllers are very expensive and much too big for tiny hands. But with the littleBits, we can build totally new and very special robot controllers that light up, flash and move—and can also tell heavy-duty industrial equipment which way to go.

So, we “hack” into the system and replace something standardized-industrialized with something that’s the outcome of DIY creativity. This project was made possible by our excellent working relationship with Ars Electronica—especially Nicole Grüneis, Christoph Froschauer and Barbara Heinzl—and by the support of KUKA CEE.

Hack the Robot

School Level: Grades 7 & up

Workshop Duration: 3 hours

Price per Person: €10; €12 for a Kombiticket that includes a tour of the Ars Electronica Center

Reservations: Beginning immediately, interested teachers can pre-register their class for dates during Winter Semester 2016-17 by calling 0732.7272.51 or via e-mail to center@aec.at. Please book at least three weeks in advance.