exhibits

-

European Artificial Intelligence Act

The AI Act is the European Union’s first comprehensive law on the regulation of Artificial Intelligence. It is intended to ensure that AI is used responsibly—for the benefit of society, without jeopardising human rights, security or democratic values.

-

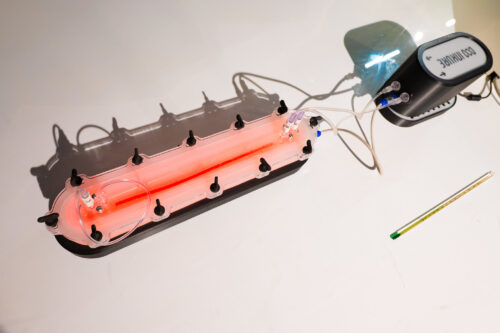

InKure – Bioreactor

This exhibit is a special bioreactor that is used to grow artificial blood vessels. A pulsating flow of nutrients is used to mature the blood vessels. In a first step, the artificial blood vessels are produced using a 4D bioprinter and then developed further in the bioreactor. For the vessels to mature properly, it is…

-

Pianographique

Pianographique is an artistic collaboration between pianists Maki Namekawa and Dennis Russell Davies and media and visualization artist Cori O’Lan. The collaboration began in 2013 and specializes in combining piano music in a concert setting with digital imagery.

-

RE_Sampling

RE_Sampling is exploring the process of cellulose production by bacteria as a way to produce yarn directly in the laboratory rather than agriculturally. This could reduce the consumption of agricultural land, water and pesticides in the future.

-

Easter Holidays at the Ars Electronica Center

To discover the world with new eyes, we are once again setting out on a journey of discovery during the Easter holidays at the Ars Electronica Center. Paint Easter eggs with a robot, track Easter nests, mix egg colors in the lab or create seed bombs to green traffic islands – Family Days promise Easter…

-

Climate-friendly cultural institution

A program of the Federal Ministry for Arts, Culture, the Civil Service and Sport, in cooperation with the Climate and Energy Fund, financed by the Recovery and Resilience Facility of the Next Generation EU Recovery Fund of the European Union

-

Active Textile Tailoring

Today’s garments are mass-produced in generic sizes and are not tailored to the individual’s body shape, needs, or comfort. Active Textile Tailoring is a system for knit garments that can be activated in the store or at home and can adapt itself to the person’s body.

-

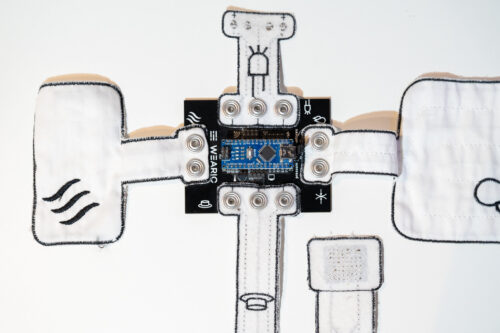

Wearic Smart Textiles Kit

Interested in making your own wearable? The Wearic Smart Textiles Kit is the world’s first do-it-yourself package with textile sensors. The kit contains sensors for pressure, wetness, heat, as well as pushbuttons and LED, which can be combined in any way.

-

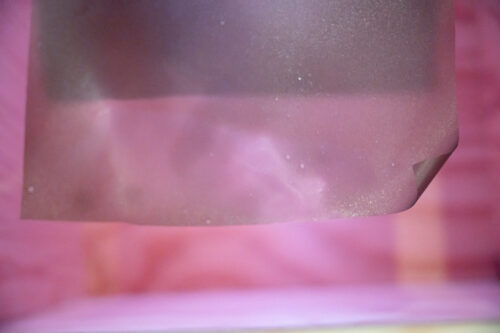

second skin

In the projects second skin the artist experiments with bio-based plastic to design clothes inspired by human skin. Bioplastic is produced from the renewable resources glycerine, water, agar, and gelatine.

-

Metamaterial Devices

The project Metamaterial Devices has created physical objects consisting of many small cells that can move together like a machine in a coordinated manner and perform a mechanical function. This is completely defined by the microstructure of the material. Thus the material becomes a machine.