In the Material Showcase of the MaterialLab, we present you a current range of future materials. Be inspired!

-

Active Textile Tailoring

Today’s garments are mass-produced in generic sizes and are not tailored to the individual’s body shape, needs, or comfort. Active Textile Tailoring is a system for knit garments that can be activated in the store or at home and can adapt itself to the person’s body.

-

FluidSolids

FluidSolids is an innovative technology developed in Switzerland to produce biodegradable composite materials. As it uses residuals and waste materials, its environmental impact is minimal.

-

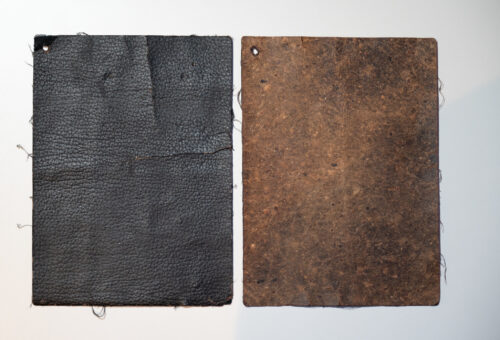

Fruitleather Rotterdam

Fruitleather Rotterdam developed a new, environmentally friendly process that converts leftover fruit into a durable leather-like material from which shoes, handbags, and other products will be made in the future.

-

Metamaterial Devices

The project Metamaterial Devices has created physical objects consisting of many small cells that can move together like a machine in a coordinated manner and perform a mechanical function. This is completely defined by the microstructure of the material. Thus the material becomes a machine.

-

MOGU Home

MOGU Home is a product line that includes elastic floor coverings, thermal insulation panels, sound-absorbing modules, decorative tiles, and wood-based materials. Only mycelia, the filamentous cells of a fungus, are used as binding material.

-

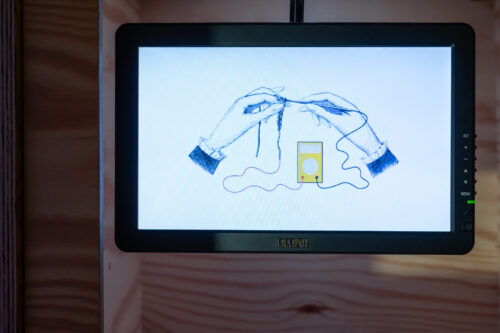

Needle Probes

Needle Probes by Irene Posch adapts tools for manual work to the needs of textile electronics and thus enables the creative expansion of the field.

-

Piñatex

Piñatex by Ananas Anam is a natural, nonwoven material made from pineapple leaf fiber which can be used as an alternative to leather and petroleum based textiles.

-

RE_Sampling

RE_Sampling is exploring the process of cellulose production by bacteria as a way to produce yarn directly in the laboratory rather than agriculturally. This could reduce the consumption of agricultural land, water and pesticides in the future.

-

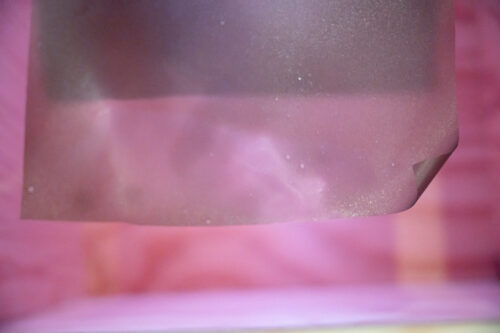

second skin

In the projects second skin the artist experiments with bio-based plastic to design clothes inspired by human skin. Bioplastic is produced from the renewable resources glycerine, water, agar, and gelatine.

-

The Meat Factory

The Meat Factory by Shahar Livne is a series of material experiments that creates a dissonance between natural and industrial production. The focus is on the production of bio leather from waste materials from the meat industry and the use of blood as a dye and plasticizer.

-

Visual Invisibility

Visual Invisibility deals with the aesthetics of molecular technology, in which biological structures are made to glow. Various textiles have been treated with additive nanoimprint technology, which makes it possible to add special functions to a surface, to produce the changing light- reflecting effects.

-

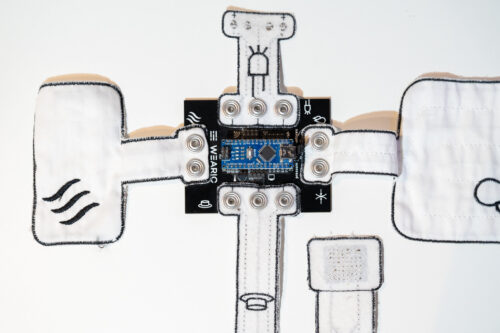

Wearic Smart Textiles Kit

Interested in making your own wearable? The Wearic Smart Textiles Kit is the world’s first do-it-yourself package with textile sensors. The kit contains sensors for pressure, wetness, heat, as well as pushbuttons and LED, which can be combined in any way.

The Material Showcase is co-funded by the European Commission’s DG CONNECT, in the framework of the Horizon 2020 programme of the European Union under the S+T+ARTS programme’s Regional STARTS Centers.