Prototyping the Future of Local, Cyclic Manufacturing

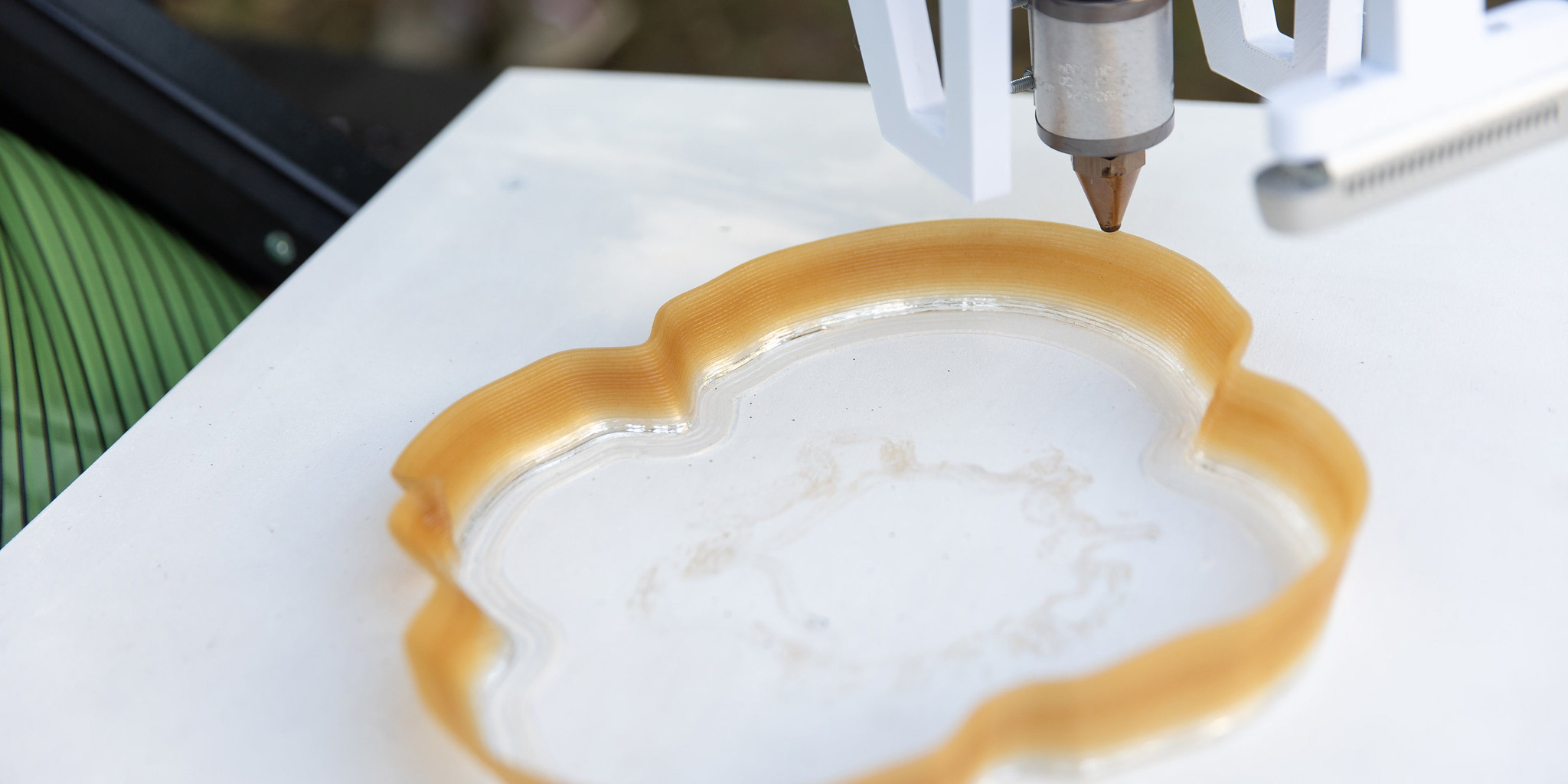

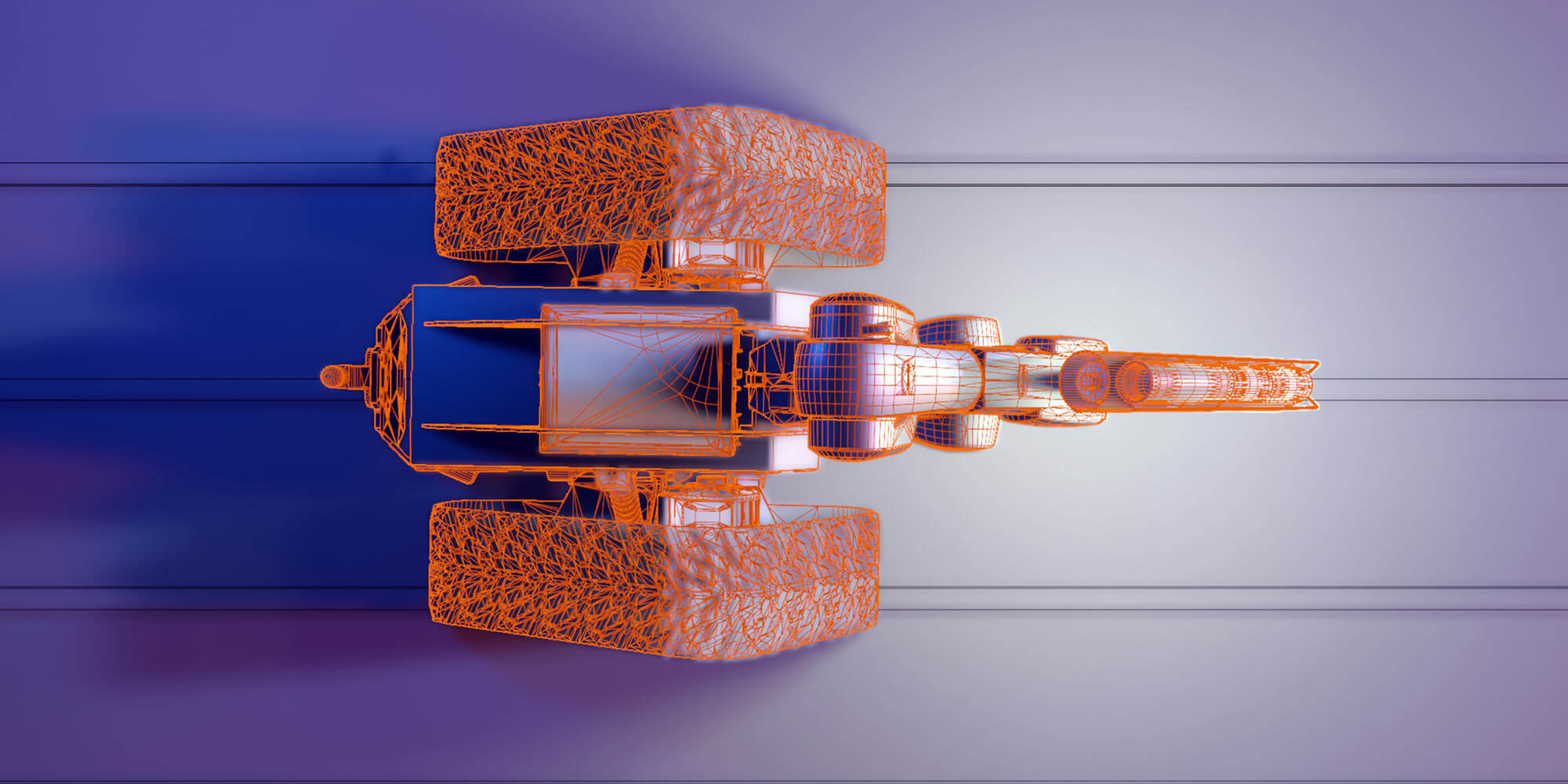

It is clear that the future of production has to be local and must be built around a circular economy. The Wandering Factory project pushes that goal a step further and relocates production directly to where it is needed, by equipping a robotic arm with an industrial 3D printer and mounting it onto an electric, tracked unmanned rover. Once there, it can autonomously fabricate objects using recycled materials, having adapted individually to the environment and the constraints of the chosen site. The system is the result of a two-month interdisciplinary collaboration among institutions, with the goal of creating a proof-of-concept for the future local fabrication. By using only products that are presently commercially available, brought together in a minimum amount of time, we showcase that the technology to make production mobile, urban, and flexible already exists – it just has to be used.

Credits

The project is part of the FabCity Initiative Linz Developed by Creative Robotics (UfG Linz), IPPE (JKU Linz) and the MHC furniture and timber construction cluster Received funding through „Leitinitiative Digitalisierung“ (Land Oberösterreich) and „DigitalWerk“ (BMBWF) Robotics: KUKA Robotics CEE – KUKA KR10R1100-2 robot with KRC5 micro eMobility: Mattro GmbH – Mattro ROVO 2 Extrusion: Noztek Ltd. – Noztek Touch Material: Wood K plus