Im MaterialLab dreht sich alles um den innovativen Umgang mit Material beziehungsweise Werkstoffen. Wer hätte gedacht, dass aus Ananasblättern eine Alternative zu Leder erzeugt werden kann? BesucherInnen können in die Welt der Materialforschung eintauchen und mit verschiedenen Produktionsmethoden experimentieren.

Wie könnte die Produktion von morgen aussehen? Nachhaltige und soziale Produktion ist vor dem Hintergrund der steigenden Ressourcenknappheit und den schlechten Arbeitsbedingungen ein bedeutendes Thema. Anstatt fertige “Out-of-the-box“-Produkte zu kaufen, werden vermehrt Technologien und Entwicklungen wichtig, die es einem ermöglichen, so viel wie möglich selbst zu produzieren. Eine interessante Entwicklung in diesem Bereich ist die Open-Source-Hardware, auch Freie Hardware genannt: Hierbei werden freie Baupläne zur Herstellung von verschiedensten elektronischen und mechanischen Teilen zur Verfügung gestellt.

Ein wichtiger Aspekt für nachhaltige Produktion ist auch die Materialforschung. Wie könnten die Werkstoffe der Zukunft aussehen? Neue Materialien, die wir zur Produktion verwenden, müssen je nach Einsatzbereich verschiedenste Bedingungen erfüllen und den ökologischen Standards entsprechen. Heute forschen wir an intelligenten (Kunst-)Stoffen oder träumen von Materialien, die unsere Bedürfnisse kennen und sich selbst an wechselnde Situationen und Umstände anpassen. Natürlich können aber auch bereits bekannte Werkstoffe durch innovative Herangehens- und Bearbeitungsweisen wieder neu entdeckt werden.

Im MaterialLab steht das lustvoll-kreative Experimentieren im Vordergrund. BesucherInnen können neue und innovative Ansätze in der Produktion und im Umgang mit Material erkunden.

Exponate

-

ALG-A Algae Architecture

Ivan Marjanovic (AT), Milena Stavric (AT)

Alginat hat, im Gegensatz zu den bereits kommerziell genutzten Mikroalgen, ein noch unentdecktes Potenzial für den Einsatz in der Architektur. Es ist das strukturgebende Element der Braunalgen und kommt in deren Zellwänden vor.

-

APeel – Biomaterial Innovation

Das Projekt APeel ist eine unabhängig entwickelte Technik, die darauf abzielt, Bioabfälle zu einem weichen und dennoch robusten lederähnlichen Material zu verarbeiten.

-

Design by Decay, Decay by Design

Andrea Ling

Design by Decay, Decay by Design ist eine Reihe von Artefakten, die designten Verfall darstellen. Sie wurden im Rahmen der Ginkgo Bioworks Creative Residency 2019 zum Thema „Wie gestaltet man eine Welt ohne Abfall?“ gefertigt.

-

Grow Whole Garments

Miriam Eichinger & Emanuel Gollob, Fashion & Robotics (AT)

Ist es möglich, Prozesse zu entwickeln, welche Bakterien in ein räumlich-textiles Objekt wachsen lassen?

-

Growing Patterns. Living Pigments.

Die textile Bakterienfärbung mit lebendigen Organismen stellt eine äußerst nachhaltige und ressourcenschonende Färbemethode dar, für die keine schädlichen Chemikalien benötigt werden.

-

Interwoven

Diana Scherer (DE/NL)

Pflanzenwurzeln als Garn, das gewebt und geflochten werden kann: Mit einer Biotechnik, die das Wachstum von Wurzeln mit Hilfe von Schablonen als Module steuert, lässt Diana Scherer künstlerische Arbeiten nach selbst entworfenen Mustern wachsen.

-

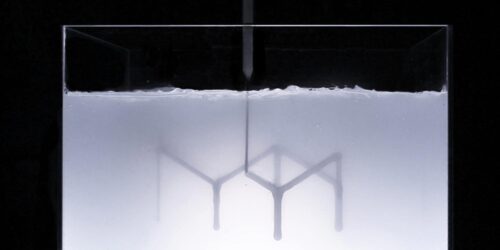

Liquid to Air / Rapid Liquid Printing

Christophe Guberan (CH)

Liquid to Air und Rapid Liquid Printing schlagen eine neue Technik vor, bei der Objekte im dreidimensionalen Raum innerhalb eines gelartigen Mediums gedruckt werden.

-

Marinero – Tailored by Weather

Jef Montes / Studio Adaptive Skins (NL)

Inspiriert vom Kontrast zwischen der Schönheit des Meeres und seiner Verschmutzung durch Plastik hat Jef Montes ein nachhaltiges Produktionssystem für „adaptive Kleidung“ entwickelt. Plastikmüll aus dem Meer, Schrumpfgarne, Seegras und andere natürliche Meeresmaterialien werden zu Garnen verarbeitet.

-

Material Showcase

Im Material Showcase des MaterialLab präsentieren wir Ihnen eine aktuelle Bandbreite zukünftiger Materialien. Lassen Sie sich von den Werkstoffen der Zukunft inspirieren!

-

MyCera

Julian Jauk (AT), Hana Vašatko (AT), Lukas Gosch (AT)

Im Projekt “MyCera” (Mycelium and Ceramics) wird ein Kompositwerkstoff aus Ton, organischem Substrat und Myzelium entwickelt. Durch 3D-Druck werden komplexe und leichte ziegelähnliche Formen erzeugt, die mit herkömmlichen Extrusionsverfahren nicht möglich wären.

-

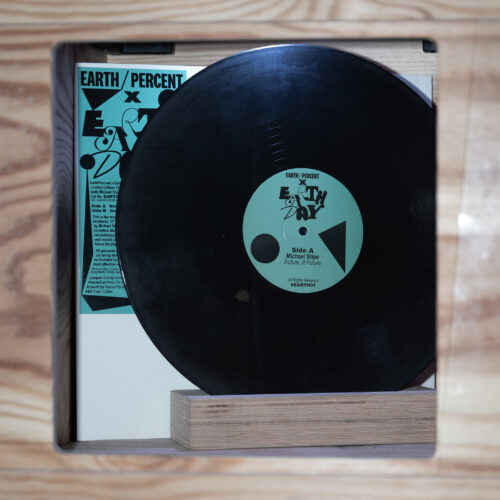

Oh My Heart by Beatie Wolfe

World’s First Bioplastic 12” record from Beatie Wolfe & Michael Stipe

Weltweit werden etwa 180 Millionen LPs aus ungefähr 30.000 Tonnen PVC pro Jahr produziert. Die erste Biokunststoff-Vinylplatte ist eine umweltfreundliche Designlösung von Evolution Music und ermöglicht Vinylaufnahmen ohne fossile Brennstoffe. Sowohl für die Musikindustrie als auch für Plattensammler ist sie eine Revolution.

-

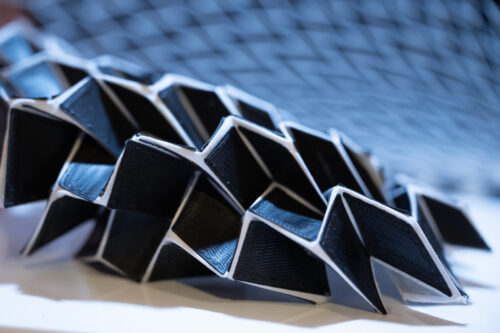

ORI*lab

Matthew Gardiner, Hideaki Ogawa, Rachel Hanlon, Erwin Reitböck, Roland Aigner. Ars Electronica Futurelab

Falten ist eine Sprache der Struktur. Dieser Grundsatz steht im Zentrum einer fortlaufenden künstlerischen Forschung, die als Orobotik bekannt ist.

-

Oribotics

Matthew Gardiner (AU)

Die „Oribotics“ reagieren, wenn sich ihnen jemand nähert. Sie ändern ihre Farbe und öffnen ihre Blüte.

-

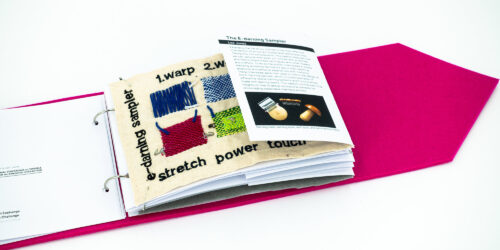

Swatchbook

Irene Posch, et al.

Was ist handwerkliche Qualität? Es ist das Wissen über Materialien, das aus der Zeit kommt, die wir im Gespräch mit ihnen verbringen.